What are the ingredients of electrophoretic paint?

In the vast world of coating technology, electrophoretic paint has become an indispensable coating choice for numerous industries due to its unique charm and wide range of applications. So, what exactly are the magical ingredients that make up electrophoretic paint? Let's lift the veil and delve into the scientific mysteries behind it.

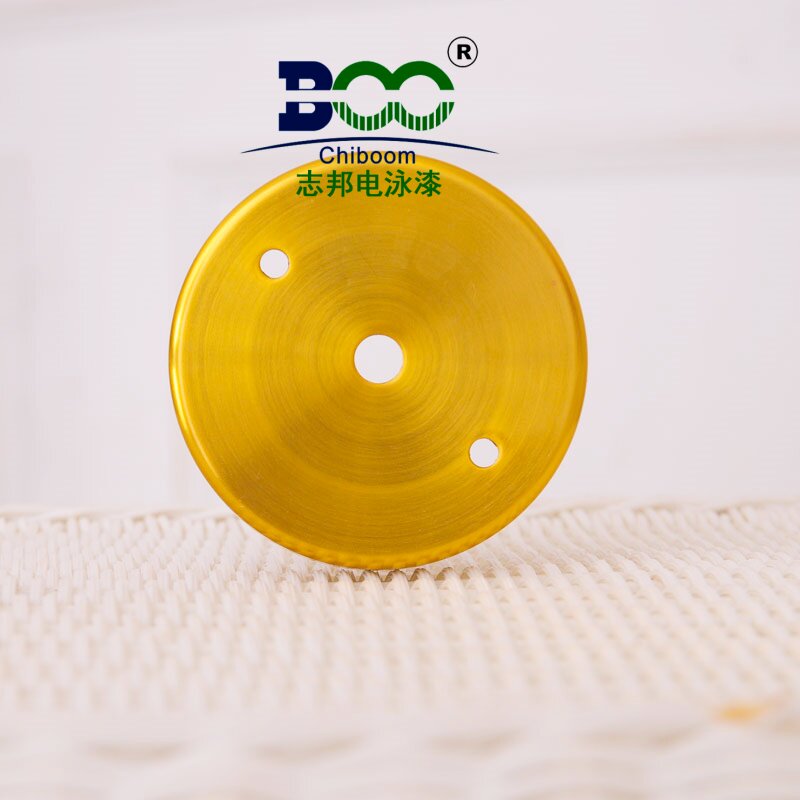

Electrophoretic paint, as the name suggests, is a type of coating that forms through electrophoretic deposition technology in a direct current electric field. Its core lies in uniformly depositing a liquid paint containing pigments, resins, and solvents onto the surface of the workpiece, creating a uniform and dense coating layer. This process is not only efficient and environmentally friendly but also imparts excellent corrosion resistance and durability to the coated workpiece.

Firstly, we cannot overlook the pigments in electrophoretic paint. Pigments are the source of color and function in electrophoretic paint. They exist in two forms: inorganic and organic pigments, providing a rich palette of colors for electrophoretic paint. Additionally, certain specific pigments can endow the coating with extra functions such as corrosion resistance and weatherability, enabling electrophoretic paint to maintain superior performance in various complex environments.

Secondly, resins serve as the backbone of electrophoretic paint, and their importance cannot be overstated. Resins primarily function as curing agents and binders in electrophoretic paint. They uniformly disperse pigments within the liquid paint and form a sturdy coating layer upon deposition. Common resin types include epoxy resins and acrylic resins, each with excellent adhesion and durability, ensuring that the electrophoretic paint coating exhibits outstanding performance on various substrates.

Of course, solvents are also an integral part of electrophoretic paint. Solvents primarily regulate the rheological properties and drying characteristics of the paint film. They enable the liquid paint to spread evenly on the surface of the workpiece and evaporate rapidly after deposition, forming a smooth and dense coating layer. However, the volatility and content of solvents must be strictly controlled to avoid adverse effects on the environment and coating quality.

In addition to these basic components, electrophoretic paint may also contain additives such as leveling agents, defoamers, and auxiliaries. These additives further improve the flowability, coatability, and surface quality of the paint, making the electrophoretic paint more stable and reliable during the coating process.

In summary, the composition of electrophoretic paint is a complex and sophisticated system. The rational ratio and use of pigments, resins, solvents, and additives collectively contribute to the excellent coating performance of electrophoretic paint. These components collaborate under the action of an electric field, uniformly depositing the liquid paint onto the workpiece to form a uniform and dense coating layer. This coating layer not only possesses excellent corrosion resistance and durability but also endows the workpiece with rich colors and unique functions.

Precisely because of these superior properties, electrophoretic paint has found widespread applications in industries such as automobiles, home appliances, and construction. It not only enhances the appearance quality of products but also extends their service life, bringing a more delightful experience to people's lives. In future developments, with continuous advancements in technology and heightened environmental awareness, electrophoretic paint is bound to showcase its unique charm and value in even more fields.

WeChat

WeChat