Electrophoretic paint composition analysis

Electrophoretic paint composition analysis

Title: Analysis of Electrophoretic Paint Composition: Exploring Efficient and Environmentally Friendly Coating Technology

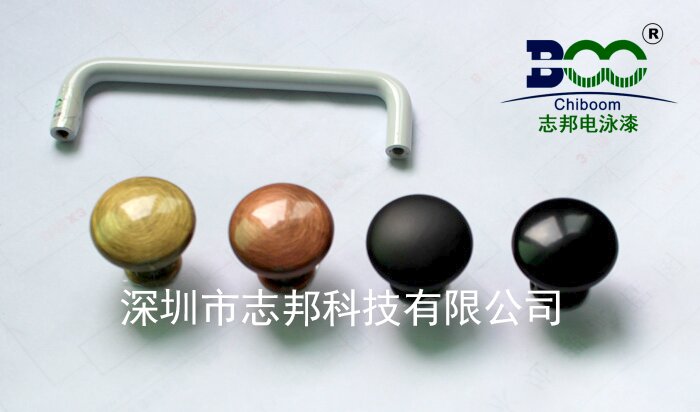

Electrophoretic paint, as an advanced coating technology, has demonstrated its unique advantages in various industrial fields such as automobiles, home appliances, and hardware since its inception. This technology utilizes the electrophoretic phenomenon to enable charged paint particles to move directionally under an electric field and deposit on the surface of the object being coated, forming a uniform and dense coating. Electrophoretic paint not only boasts excellent corrosion resistance, weather resistance, and decorative properties but also stands out for its efficiency and environmental friendliness. This article delves into the primary components of electrophoretic paint, exploring how they contribute to these remarkable characteristics.

I. Resin Components

Resin serves as the primary film-forming substance in electrophoretic paint, determining the basic properties of the coating such as hardness, adhesion, and weather resistance. Common resins used in electrophoretic paint include epoxy resins, acrylic resins, and polyurethane resins. These resins form a three-dimensional network structure through crosslinking reactions, imparting the coating with good mechanical strength and chemical stability. Among them, epoxy resins are highly valued for their superior corrosion resistance, chemical resistance, and excellent adhesion.

II. Pigments and Fillers

Pigments provide electrophoretic paint with color and hiding power, while fillers are used to improve the physical properties of the coating and reduce costs. The selection of pigments must consider their weather resistance, dispersibility, and compatibility with resins. Fillers such as talc powder and calcium carbonate not only increase the thickness and hardness of the coating but also enhance its wear resistance and scratch resistance. By adjusting the ratio of pigments and fillers, the appearance and cost-effectiveness of the coating can be optimized.

III. Additives

Additives play a crucial role in electrophoretic paint, significantly impacting the performance of the coating despite their small usage amounts. Common additives include wetting and dispersing agents, defoamers, leveling agents, and curing agents. Wetting and dispersing agents facilitate the uniform dispersion of pigments and fillers, improving the stability and workability of the paint. Defoamers eliminate bubbles generated during mixing and application. Leveling agents enhance the leveling properties and gloss of the coating. Curing agents, meanwhile, are essential for promoting the crosslinking and curing of resins, forming a stable coating.

IV. Solvents

Solvents primarily dissolve resins and adjust the viscosity of electrophoretic paint. Traditional electrophoretic paints often use organic solvents such as alcohols and ethers, but these solvents can volatilize during use, posing potential risks to the environment and human health. With increasing environmental awareness, water-based electrophoretic paints have emerged, using water as the solvent, significantly reducing VOC (Volatile Organic Compound) emissions and aligning with green coating requirements.

V. Electrolytes

Electrolytes are indispensable components in electrophoretic paint, providing the electric field environment necessary for the directional movement of paint particles. During the electrophoretic process, electrolytes and paint particles constitute a complex electrochemical system. By adjusting the type and concentration of electrolytes, the electrophoretic speed and deposition efficiency of the paint can be controlled.

Conclusion

Electrophoretic paint, with its unique coating process and outstanding performance, plays an increasingly important role in modern industries. Through a thorough analysis of its components, we can gain a deeper understanding of its working principles and performance characteristics, providing valuable support for optimizing paint formulations and enhancing coating quality. In the future, with stricter environmental regulations and continuous technological advancements, electrophoretic paint will continue to evolve towards greater environmental friendliness, efficiency, and intelligence.

WeChat

WeChat