What material is electrophoretic paint made of?

What material is electrophoretic paint made of?

Electrophoretic Paint: An Innovative Coating Material

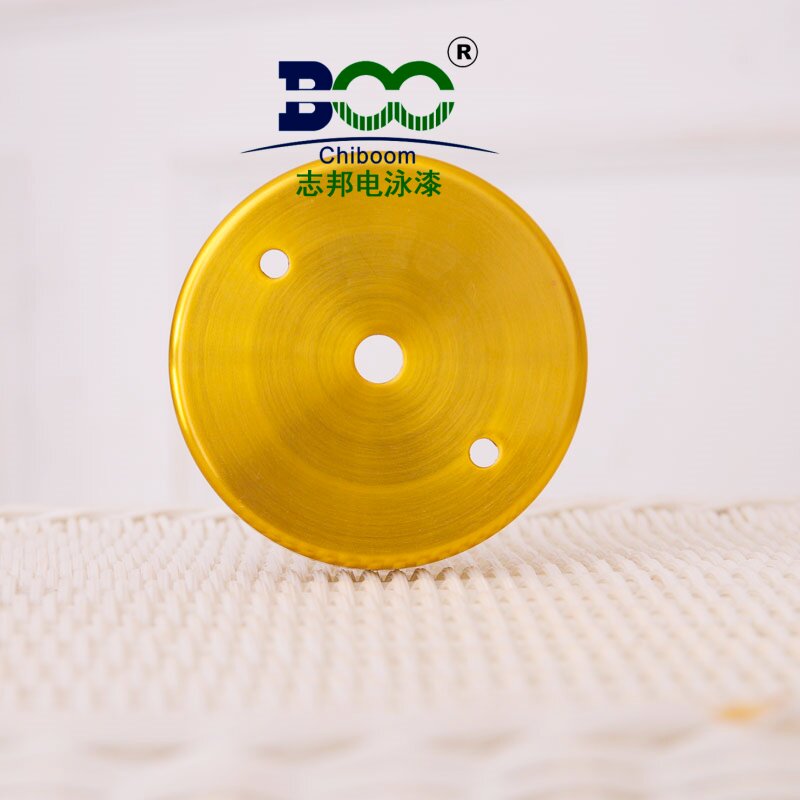

Electrophoretic paint, as an innovative coating material, has been widely used in various fields in recent years, especially in automobile and home appliance manufacturing. Its unique process and superior performance have made electrophoretic paint stand out among many coatings, becoming an important choice for modern industrial coating.

The generation of electrophoretic paint is mainly based on the principle of electrophoresis, which involves the directional movement of charged paint particles in an electric field and their deposition on the surface of a workpiece to form a uniform paint film. In this process, the components of electrophoretic paint play a crucial role.

Electrophoretic paint is mainly composed of resins, pigments, additives, and solvents. Among them, the resin is the main film-forming material of electrophoretic paint, which determines the performance and appearance of the paint film. Pigments give the paint film color and opacity, enabling electrophoretic paint to meet the personalized needs of different customers. Additives are used to improve the application performance and stability of electrophoretic paint, ensuring the quality and durability of the coating. Solvents are used to adjust the viscosity of electrophoretic paint, facilitating its application and coating.

During the production of electrophoretic paint, a series of chemical reactions and physical treatments are also involved. For example, adjusting the pH value and conductivity of electrophoretic paint can control the charge and motion speed of paint particles, resulting in the desired coating effect. At the same time, precise control of coating thickness and uniformity can be achieved by controlling the parameters of the electrophoretic process, such as voltage, time, and temperature.

The superior performance of electrophoretic paint is mainly reflected in several aspects. Firstly, it exhibits excellent adhesion and corrosion resistance, effectively protecting workpieces from external environmental erosion. Secondly, the coating of electrophoretic paint is uniform and delicate, possessing good decorative effects. Furthermore, the high efficiency of electrophoretic paint application can significantly reduce coating costs and time.

Due to these advantages, electrophoretic paint has been widely used in various fields. In automobile manufacturing, electrophoretic paint is used for coating car bodies and components, not only improving the corrosion resistance of products but also giving vehicles a unique appearance. In home appliance manufacturing, electrophoretic paint is also widely used for coating the shells of products such as refrigerators and washing machines, enhancing the overall quality and competitiveness of these products.

However, the application of electrophoretic paint also faces some challenges. For example, how to further improve the weather resistance and wear resistance of electrophoretic paint to meet more stringent usage environments? How to reduce the production cost of electrophoretic paint to promote its application in a wider range of fields? These issues require continuous research and exploration.

Overall, electrophoretic paint, as an innovative coating material, has broad application prospects and development space. With continuous technological advancements and process optimizations, the performance and quality of electrophoretic paint will be further improved, bringing more possibilities to modern industrial coating.

WeChat

WeChat