What is electrophoretic paint?

What is electrophoretic paint?

Electrophoretic Paint: What It Is, Applications, and Production Process

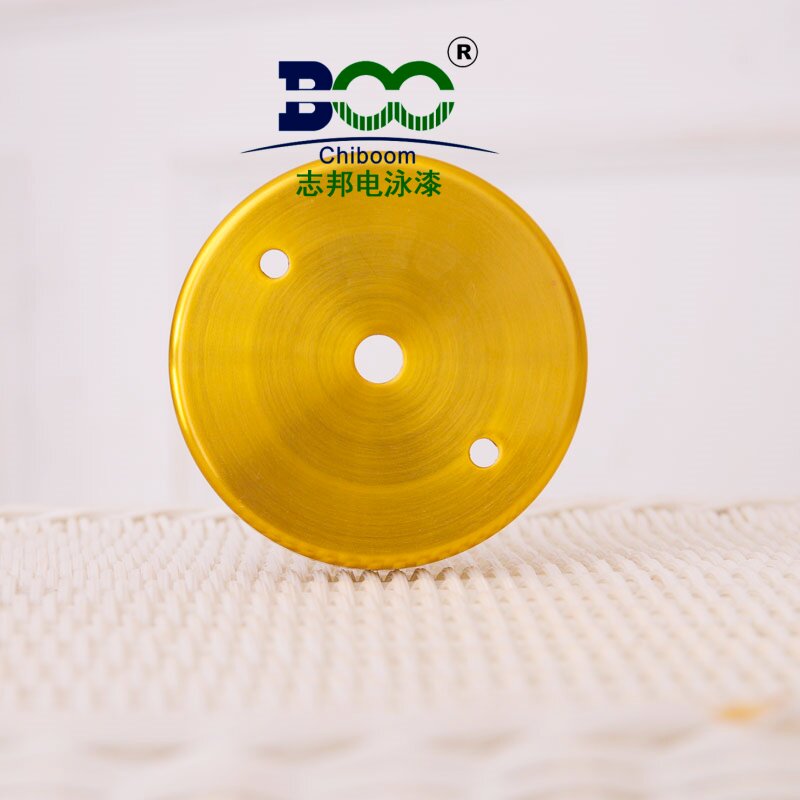

Electrophoretic paint, also known as electrophoretic coating, is a special type of paint that is primarily used in industrial manufacturing for surface treatment. It utilizes the principles of electrochemistry to deposit a uniform coating on the surface of a workpiece through the migration of charged particles in an electric field. This coating aims to enhance corrosion resistance, aesthetics, and material performance. This article provides a detailed overview of electrophoretic paint, its applications, and production process.

I. Definition of Electrophoretic Paint

Electrophoretic paint is a specialized type of paint that utilizes electrochemical reactions to form a uniform coating on the surface of a workpiece. This coating offers exceptional properties such as high corrosion resistance, wear resistance, strong adhesion, and excellent appearance. Electrophoretic paint has found widespread applications across various industries, particularly in automotive manufacturing, home appliances, construction, and medical devices.

II. Applications of Electrophoretic Paint

Automotive Manufacturing: The bodies, frames, and wheels of automobiles require corrosion-resistant treatments to enhance their lifespan. Electrophoretic paint offers excellent corrosion resistance and is widely used in the automotive industry.

Home Appliances: Metal components in home appliances such as washing machines, refrigerators, and air conditioners require corrosion-resistant and aesthetically pleasing surface treatments. Electrophoretic paint is well-suited for this purpose due to its wear resistance and good appearance.

Construction: Metal structures in the construction sector such as steel structures, bridges, and highway barriers require corrosion-resistant and decorative surface treatments. Electrophoretic paint offers excellent corrosion resistance and is widely used in the construction industry.

Medical Devices: Metal components in medical devices such as surgical instruments and examination equipment require surfaces with good performance characteristics for reliability and safety. Electrophoretic paint provides strong adhesion and wear resistance, making it suitable for use in the medical device industry.

III. Production Process of Electrophoretic Paint

The production process of electrophoretic paint typically involves the following steps:

Preparation of pigments: Pigments are mixed with a suitable resin to create a color paste. The type and quantity of pigments used directly impact the color and performance of the coating.

Solubilization and dispersion: The resin is dissolved in an appropriate solvent, and the color paste along with other additives is added and stirred to ensure thorough mixing and dispersion, resulting in a uniform paint.

Electrophoretic coating: The workpiece is immersed into the electrophoretic paint contained in a coating bath. Under the influence of an electric field, charged particles deposit onto the surface of the workpiece, forming a uniform coating. The intensity and duration of the electric field are controlled to achieve the desired coating thickness and properties.

Curing: The coated workpiece undergoes a curing process involving heating to promote cross-linking and curing of the coating, enhancing its performance and durability.

Post-processing: Any necessary post-processing steps such as polishing or buffing are performed to enhance the appearance and performance of the coating.

IV. Future Developments

With technological advancements and increasing environmental awareness, the production processes and techniques for electrophoretic paints are constantly evolving. Future developments in electrophoretic paints are expected to focus on higher efficiency, environmental friendliness, and increased automation. New types of electrophoretic paints will continue to emerge, catering to diverse industry needs and customer preferences. Furthermore, with the rise of industrial automation and smart manufacturing, the automation level for electrophoretic paint application processes will increase, leading to improved production efficiency and reduced labor costs. Additionally, stricter environmental regulations will encourage businesses to adopt more environmentally sustainable production methods, driving the development of greener electrophoretic paint processing techniques.

In summary, electrophoretic paint remains a vital surface treatment technology in industrial manufacturing and surface finishing industries. Through ongoing technological innovations and refinements, electrophoretic paints are expected to expand their applications and make greater contributions to industrial manufacturing and surface treatment sectors.

WeChat

WeChat