Electrophoretic Paint Agglomeration: Causes, Analysis, and Solutions

Electrophoretic painting, also known as electrocoating, is an important surface treatment process in modern industry. Its efficiency, uniformity, and environmental friendliness make it widely used in fields such as automobiles, home appliances, hardware, and medical devices. However, in actual production, the problem of electrophoretic paint agglomeration occasionally occurs, which seriously affects production efficiency and coating quality. What are the causes of electrophoretic paint agglomeration? How can it be effectively prevented and resolved? This article will delve into the causes of electrophoretic paint agglomeration and provide corresponding solutions.

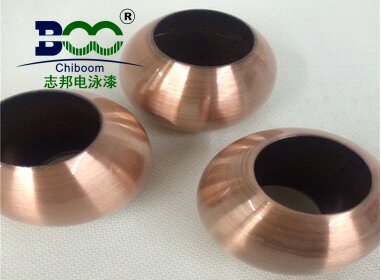

First, we need to understand the basic composition and working principle of electrophoretic paint. Electrophoretic paint mainly consists of resins, pigments, solvents, and additives. The resin acts as the film-forming material, the pigment provides color and hiding power to the film, the solvent dissolves the resin and adjusts the paint’s viscosity, and additives are used to improve the performance of the paint and the coating effect. During the electrophoretic painting process, the workpiece is immersed in an electrically charged paint bath. Under the influence of the electric field, the charged paint particles move towards the surface of the workpiece and deposit, forming a uniform paint film.

The formation of electrophoretic paint agglomeration is mainly related to the following aspects: the characteristics of the paint itself, for example, a high molecular weight and wide distribution of the resin can lead to high paint viscosity, poor fluidity, and a tendency to form gels or agglomerates during storage or transportation; poor pigment dispersion, the dispersion of pigments in the paint directly affects the coating effect, and poorly dispersed pigments tend to aggregate… and form agglomerates; violent shaking during transportation, violent shaking during transportation can cause collisions and aggregation of pigments and resins in the paint, leading to agglomeration. Equipment issues also need attention, for example, a failure of the agitation equipment can lead to uneven mixing of the paint, which can easily cause agglomeration; clogged filter equipment can prevent the timely removal of impurities in the paint, affecting the stability of the paint and the quality of the coating.

After understanding the causes of electrophoretic paint agglomeration, we can take the following measures for prevention and resolution: choosing high-quality electrophoretic paint, selecting electrophoretic paint with moderate molecular weight, uniform distribution, good pigment dispersion, appropriate solvent volatility, and reasonable selection of additives; controlling storage and transportation conditions, storing electrophoretic paint in a cool, dry, and well-ventilated place, avoiding direct sunlight and high temperatures, controlling the storage temperature within an appropriate range, avoiding excessively long storage times, and avoiding violent shaking during transportation; optimizing coating process parameters, selecting appropriate voltage, electrophoretic time, and paint solid content according to the size, shape, and material of the workpiece, ensuring sufficient paint agitation; regularly maintaining equipment, regularly inspecting and maintaining agitation and filtration equipment to ensure its proper operation.

Electrophoretic paint agglomeration is a complex process issue that requires analysis and prevention from multiple aspects. By strictly controlling the quality of raw materials, optimizing process parameters, strengthening equipment maintenance, and production management, the occurrence of electrophoretic paint agglomeration can be effectively reduced, production efficiency and product quality can be improved, and greater economic benefits can be created for the enterprise. It is hoped that the introduction of this article can help everyone better understand and solve the problem of electrophoretic paint agglomeration, and promote the further development of electrophoretic painting technology.

WeChat

WeChat