The Characteristics of Electrophoretic Paint: A Perfect Fusion of Technology and Aesthetics

In today's industrial manufacturing sector, electrophoretic paint technology, with its unique charm and broad application prospects, has become a stunning landscape. As an advanced coating process, electrophoretic paint not only boasts exceptional corrosion resistance but also provides products with outstanding decorative effects, achieving a perfect fusion of technology and aesthetics. This article will delve into the characteristics of electrophoretic paint and show you the unique charm of this technology.

One of the notable characteristics of electrophoretic paint is its outstanding corrosion resistance. Whether in automobile manufacturing, furniture production, or electronic appliances and building materials, electrophoretic paint can provide a solid corrosion barrier for products. Its unique electrophoretic deposition principle allows the paint film to tightly adhere to the surface of the workpiece, forming a uniform and dense protective layer that effectively isolates corrosive substances such as oxygen and moisture in the air, thereby extending the product's lifespan.

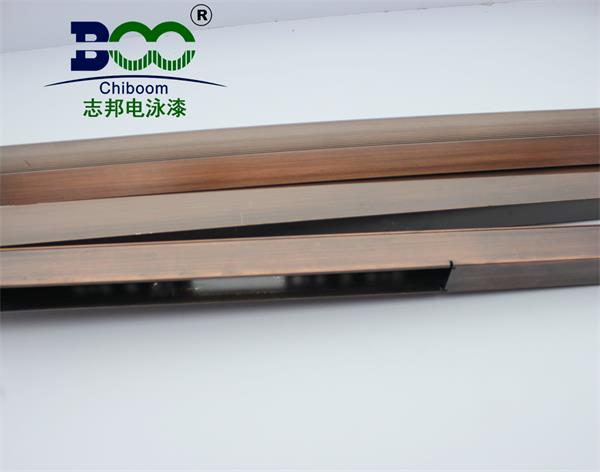

In addition to corrosion resistance, the decorative effects of electrophoretic paint are also remarkable. By adjusting the formula and process parameters of electrophoretic paint, a rich variety of colors and textures can be easily achieved. Whether it's a calm and elegant metallic color or a fresh and bright solid color, electrophoretic paint can perfectly present them. Meanwhile, electrophoretic paint also boasts excellent gloss and smoothness, making the product surface smoother and more delicate, enhancing the overall aesthetics of the product.

The environmental friendliness of electrophoretic paint technology is also one of the reasons it is highly praised. Compared to traditional spray painting processes, electrophoretic paint can significantly reduce emissions of volatile organic compounds, lowering environmental pollution. Furthermore, the utilization rate of electrophoretic paint is relatively high, reducing paint waste and aligning with modern society's pursuit of green and sustainable development.

Electrophoretic paint technology also features high efficiency and high-quality production. The electrophoretic coating process employs automated production lines, greatly improving production efficiency and reducing labor costs. At the same time, electrophoretic paint films have uniform thickness and strong adhesion, making the coating quality of products more stable and reliable. This not only enhances the market competitiveness of products but also brings more economic benefits to enterprises.

Of course, the application of electrophoretic paint technology also requires attention to certain issues. For example, the formula and process parameters of electrophoretic paint need to be carefully designed and adjusted according to the specific needs and process characteristics of the product. Meanwhile, electrophoretic coating production lines also require regular maintenance to ensure stable operation and extend service life.

With the continuous advancement of technology and the increasing aesthetic demands of people, electrophoretic paint technology is also constantly innovating and developing. In the future, we can expect electrophoretic paint to be widely applied in more fields, bringing more beauty and surprises to people's lives.

In summary, electrophoretic paint technology, with its exceptional corrosion resistance, outstanding decorative effects, environmentally friendly production methods, and high-efficiency, high-quality production characteristics, has become an indispensable part of modern industrial manufacturing. It not only enhances product quality and market competitiveness but also creates a more beautiful living environment for people. Let us jointly look forward to electrophoretic paint technology shining even more brilliantly in future developments!

WeChat

WeChat