Electrophoretic Paint Film Thickness Standards

In the rapid development of today's manufacturing industry, electrophoretic paint, as an efficient and environmentally friendly surface treatment technology, is widely used in various fields such as automobiles, household appliances, and hardware. The thickness of the electrophoretic paint film, as a critical indicator for evaluating the quality of electrophoretic paint films, holds great significance in ensuring product quality and enhancing corrosion resistance. Recently, the latest regulations on electrophoretic paint film thickness standards have been officially issued, providing clearer technical guidance for the electrophoretic coating industry.

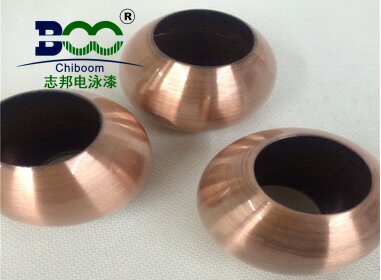

Electrophoretic paint is a coating technology that deposits paint particles on the surface of the workpiece through electrophoresis. During the electrophoretic coating process, the workpiece is immersed as a cathode or anode in an electrolytic bath containing electrophoretic paint, and by applying voltage, the paint particles are charged and move directionally, ultimately depositing on the surface of the workpiece to form a uniform and dense paint film. The thickness of the electrophoretic paint film not only affects the appearance quality of the product but is also directly related to its corrosion resistance and service life.

According to the latest regulations, the standards for electrophoretic paint film thickness vary depending on product type and requirements. Generally, the thickness of the electrophoretic paint layer ranges between 15 and 25 micrometers. However, for some special products, such as automotive products, which have higher requirements for corrosion resistance, the electrophoretic coating film thickness is generally above 20 micrometers, and even a single-layer electrophoretic coating film thickness is required to reach 35 to 60 micrometers or more. The formulation of these standards fully considers the corrosion resistance needs of different products, ensuring the best effect of electrophoretic paint in various application scenarios.

The control of electrophoretic paint film thickness not only depends on the performance of the paint itself but is also closely related to the coating process, equipment conditions, and the skill level of operators. To ensure the accuracy and consistency of electrophoretic paint film thickness, enterprises need to adopt advanced coating equipment and processes and strengthen the training and management of operators. At the same time, enterprises should also establish a sound detection system, regularly detect and evaluate the thickness of electrophoretic paint films, and promptly identify and resolve issues.

In the detection process of electrophoretic paint film thickness, commonly used methods include magnetic thickness gauges and eddy current thickness gauges. These detection methods have the advantages of easy operation, accurate measurement, and good repeatability, providing reliable data support for enterprises. However, it should be noted that different detection methods may have certain error ranges, so in practical applications, they need to be selected and calibrated based on product types and requirements.

The formulation and implementation of electrophoretic paint film thickness standards not only help improve product quality and corrosion resistance but also promote the healthy development of the electrophoretic coating industry. In the future, with the continuous upgrading of the manufacturing industry and increasingly stringent environmental protection requirements, electrophoretic paint film thickness standards will be further improved and optimized, providing more scientific and reasonable technical guidance for the electrophoretic coating industry. At the same time, enterprises should also actively respond to national policies and market demands, strengthen technological innovation and quality management, and continuously improve the level and competitiveness of electrophoretic coating technology.

WeChat

WeChat