Causes of Roughness in Electrophoretic Paint Film

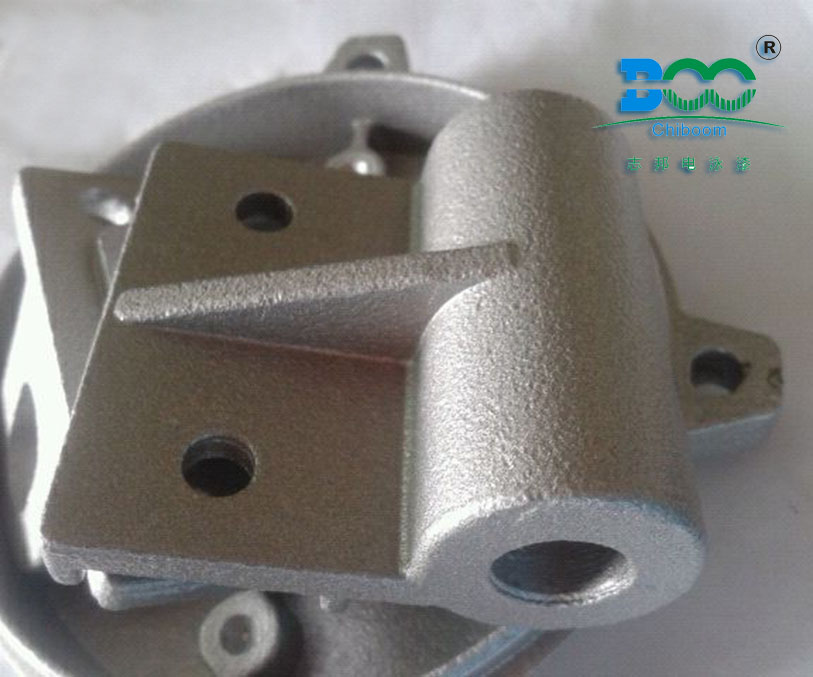

In the intricate world of modern manufacturing processes, electrophoretic paint, with its high efficiency, environmental friendliness, and exceptional corrosion resistance, has found widespread application in industries such as automobiles, home appliances, and hardware. However, a challenge occasionally encountered during electrophoretic coating – rough paint film – frequently troubles technicians and manufacturers. This phenomenon not only detracts from the product's aesthetic appeal but may also pose potential threats to the durability and functionality of the coating. So, why does electrophoretic paint film become rough? And how can we tackle this challenge?

Firstly, the roots of rough electrophoretic paint film often lie in multiple aspects. From the quality of the electrophoretic paint itself, factors such as pigment dispersion, filler particle size distribution, and resin solubility can directly impact the smoothness of the paint film. If the solid particles in the electrophoretic paint are unevenly distributed or contain undissolved resins, impurities, etc., these particles will deposit on the workpiece surface during the electrophoretic process, resulting in a rough paint film. Additionally, the formulation design, production process, and storage conditions of the electrophoretic paint also play important roles in paint film quality.

On the other hand, operational parameters during the electrophoretic process cannot be overlooked. The settings for voltage, current density, and electrophoretic time must be precise to ensure that the paint film deposits evenly and smoothly on the workpiece. Excessively high voltage may lead to an overly thick paint film, causing roughness, while uneven current density or prolonged electrophoretic time may result in excessive local deposition, also affecting the smoothness of the paint film.

Furthermore, the condition of the electrophoretic tank and its circulation system is a crucial factor influencing paint film quality. If the inner walls of the electrophoretic tank are contaminated with old paint film, impurities, or other pollutants, or if the filtration devices in the circulation system fail to effectively remove impurities and particles from the electrophoretic solution, these contaminants will deposit on the workpiece surface during the electrophoretic process, leading to rough paint film.

To address the issue of rough electrophoretic paint film, we need to adopt comprehensive solutions. Firstly, we should strictly control the quality of the electrophoretic paint, selecting products with stable performance and reliable quality, and strengthening cooperation with suppliers to jointly optimize the formulation and production process of the electrophoretic paint. Secondly, we should precisely control the various parameters during the electrophoretic process to ensure that the paint film deposits evenly and smoothly on the workpiece. At the same time, we should regularly clean and maintain the electrophoretic tank and circulation system to maintain their cleanliness and good working condition.

In addition, we should also pay attention to the control of the coating environment. By adjusting the temperature, humidity, and other environmental conditions in the coating workshop, we can reduce the influence of external factors on the electrophoretic process. Maintaining the cleanliness of the coating workshop is also crucial to prevent dust, fibers, and other contaminants from entering the electrophoretic tank and affecting paint film quality.

In conclusion, rough electrophoretic paint film is a complex and intricate issue that requires us to address from multiple angles. By enhancing the quality of electrophoretic paint, precisely controlling electrophoretic parameters, strengthening the maintenance of electrophoretic tanks and circulation systems, and optimizing the coating environment, we can effectively reduce the occurrence of rough electrophoretic paint film and improve the overall quality and stability of the coating process. In this process, continuous technological innovation and practical exploration will provide us with more solutions and ideas, driving the development of electrophoretic coating technology to higher levels.

WeChat

WeChat