What is electrophoretic paint processing?

What is electrophoretic paint processing?

Electrocoat Processing: Technology, Applications and Future Developments

Electrophoretic coating processing is a widely used surface treatment technology in the industrial manufacturing field. It utilizes the principle of electrochemistry to make charged particles move directionally under the action of an electric field and form a uniform coating on the surface of workpieces, aiming to achieve purposes such as corrosion resistance, aesthetics, and enhancing material properties. This article will provide a detailed introduction to the basic principles of electrophoretic coating processing, technical characteristics, application fields, and future development trends.

I. Basic Principles of Electrophoretic Coating Processing

Electrophoretic coating processing mainly involves two processes: electrophoretic coating and electrodeposition. Electrophoretic coating is a method that utilizes the principle of charged particles moving directionally in an electric field to coat particles onto the surface of workpieces. Electrodeposition, on the other hand, is a process that utilizes electrolysis to make charged particles deposit on the surface of workpieces to form a solid and uniform coating. In this process, charged particles move towards the electrode under the action of electric fields and deposit on the electrode to form a coating.

II. Technical Characteristics of Electrophoretic Coating Processing

High coating efficiency: Electrophoretic coating processing can complete large-area coating in a short time, improving production efficiency.

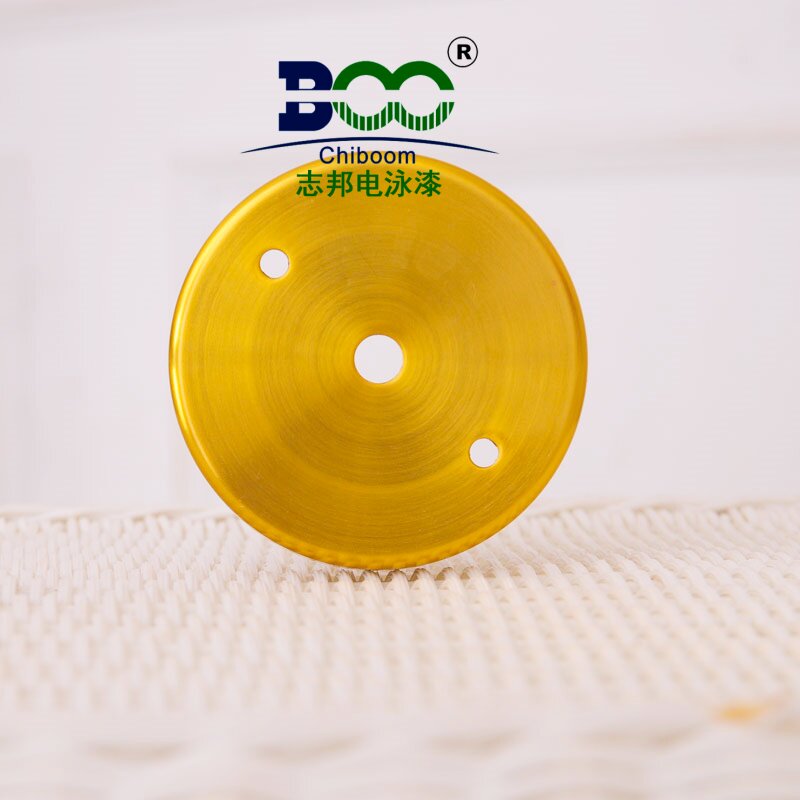

Uniform coating: Due to the electric field, the deposited paint particles are uniform on the surface of the workpiece, forming a uniform coating.

High paint utilization rate: The paint utilization rate of electrophoretic coating processing can reach over 90%, reducing waste.

Environmental protection: Electrophoretic coating processing produces less wastewater and is easy to treat, in line with environmental protection requirements.

III. Application Fields of Electrophoretic Coating Processing

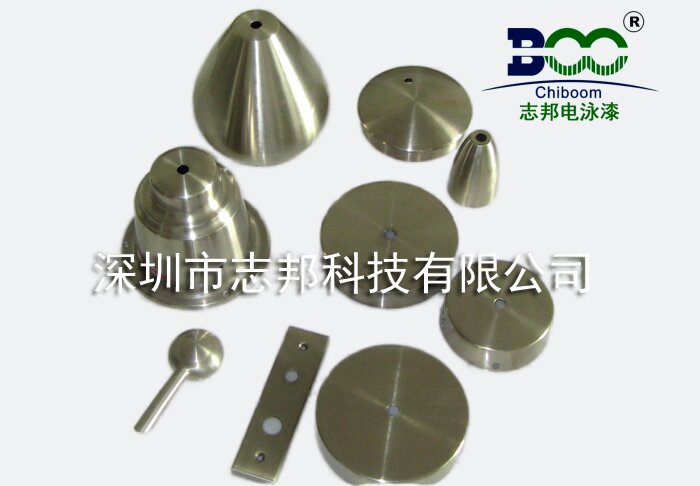

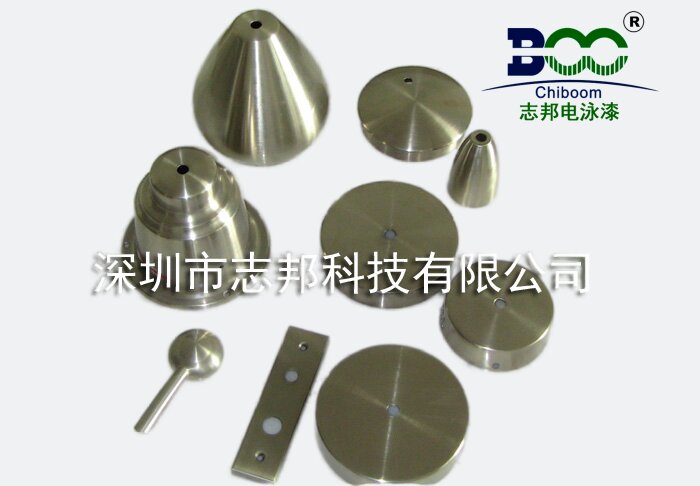

Automobile manufacturing: The car body, frame, and wheels of automobiles commonly use electrophoretic coating processing for corrosion resistance and aesthetic purposes.

Household appliances: Electrophoretic coating processing is widely used in the metal parts of washers, refrigerators, air conditioners, and other household appliances for corrosion resistance and aesthetic purposes.

Metal products: The surfaces of metal products such as doors, windows, guardrails, and staircases are commonly treated with electrophoretic coating processing for corrosion resistance and aesthetic purposes.

Construction industry: The surfaces of metal structures such as steel structures, bridges, highway guardrails, and other metal structures are often treated with electrophoretic coating processing for corrosion resistance and decorative purposes.

Medical devices: Metal parts in medical devices such as surgical instruments, examination equipment, and other medical devices often use electrophoretic coating processing for surface treatment.

IV. Future Development Trends

With the advancement of technology and increasing environmental awareness, electrophoretic coating processing technology will continue to develop and improve. In the future, electrophoretic coating processing will develop towards higher efficiency, environmental friendliness, and intelligence. New types of electrophoretic coatings will continue to emerge to meet the needs of different industries and customers. At the same time, with the promotion of industrial automation and intelligent manufacturing, the automation level of electrophoretic coating processing will be further improved, increasing production efficiency and reducing labor costs. Additionally, stricter environmental regulations will encourage companies to pay more attention to environmentally friendly production, promoting the green development of electrophoretic coating processing technology.

In conclusion, as an important surface treatment technology, electrophoretic coating processing will continue to play an important role in the future. Through continuous technological innovation and improvement, it is believed that electrophoretic coating processing will be applied and promoted in more areas, making greater contributions to the development of the industrial manufacturing and surface treatment industries.

WeChat

WeChat